concrete pump: A Global Game-Changer in Construction Evolution

The construction industry is often viewed as a symbol of manual labor, brick-by-brick progress, and traditional methods passed down through generations. However, one innovation has quietly but profoundly changed the way concrete is delivered and applied on job sites around the world—the concrete pump. This powerful machine has transformed the construction process from a time-consuming, labor-intensive operation into a streamlined, efficient, and precise activity.

As urbanization accelerates and infrastructure demands grow, the concrete pump stands out as a critical technology not only in developed nations but also in emerging markets. This article explores the history, global impact, and future potential of the concrete pump in revolutionizing construction practices worldwide.

The origin of the concrete pump

Before the advent of concrete pumps, concrete was moved using wheelbarrows, buckets, and hoists. These manual methods were slow, inconsistent, and physically demanding. The invention of the concrete pump in the early 20th century was a pivotal moment in construction history.

The first practical concrete pump was developed in Germany in the 1920s. This device used mechanical pistons to push liquid concrete through steel pipes, greatly improving delivery time and reducing spillage. As construction projects became more complex, particularly with the post-World War II building boom in Europe, the demand for more advanced concrete pumping solutions increased.

See also: The Importance of Regular Commercial Cleaning for Your Business

Global adoption and industry transformation

Today, concrete pump technology is used across every continent. Its applications range from small residential homes to megaprojects like skyscrapers, airports, tunnels, and dams. Let’s take a look at how different regions have adopted this innovation:

North America

In the United States and Canada, the concrete pump is a staple on nearly every major construction site. Boom pumps dominate high-rise developments, while trailer-mounted line pumps are frequently used in suburban housing and highway construction.

The North American market values automation and labor savings. Regulations regarding worksite safety and productivity further drive adoption of concrete pump technologies. Today, the U.S. leads in remote-control pump usage and advanced monitoring systems.

Europe

Europe is home to some of the earliest manufacturers of concrete pumps, including industry giants from Germany and Italy. Countries like Switzerland and the Netherlands, with their dense urban areas, rely on pumps to navigate tight construction zones.

In addition, Europe’s push for sustainability and efficiency has driven innovation in electric-powered and hybrid concrete pump models, contributing to reduced carbon emissions on job sites.

Asia-Pacific

In fast-growing economies like China, India, Indonesia, and Vietnam, concrete pumps are essential for mass urban development. Skyscrapers, bridges, industrial zones, and high-speed rail networks depend heavily on fast and continuous concrete delivery.

Manufacturers in Asia are rapidly expanding production capacity, offering competitive pricing and exporting equipment globally. China, for example, now produces some of the highest-capacity boom pumps in the world.

Middle East and Africa

With large-scale developments like Dubai’s skyscrapers and Africa’s emerging cities, the need for efficient concrete placement is crucial. In regions with extreme heat or challenging terrain, concrete pumps minimize delays and protect concrete quality by ensuring faster placement before setting begins.

Types of concrete pump technologies

The evolution of the concrete pump has led to a variety of types, each suitable for specific tasks and environments:

Boom Pumps

Equipped with a robotic arm (boom), these pumps are mounted on trucks and can deliver concrete across great distances or heights—ideal for tall buildings, flyovers, and bridges.

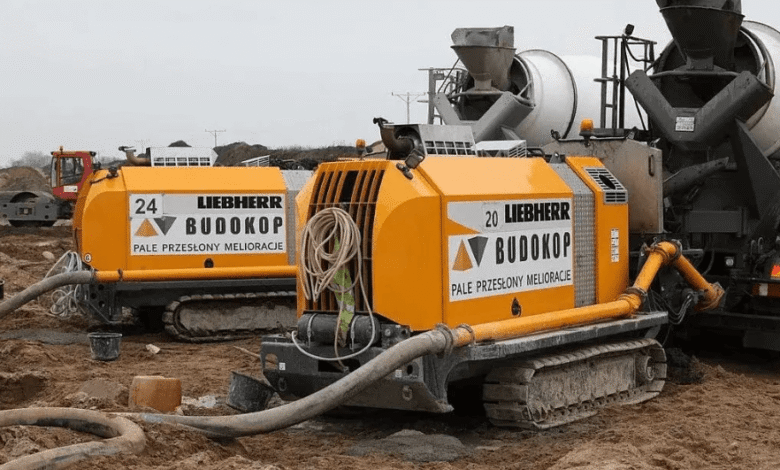

Line Pumps

Also known as trailer-mounted pumps, these are best suited for smaller projects or areas with tight access. Concrete flows through flexible hoses to the pour site.

Challenges in global adoption

Despite the advantages, some regions still rely on traditional concrete placement methods due to:

- High initial cost of equipment

- Lack of skilled operators or training

- Limited access to spare parts or maintenance services

- Resistance to change in conventional construction markets

However, as more projects demand fast turnaround and compliance with environmental and safety standards, these challenges are gradually being addressed.

The future of concrete pump technology

Innovation continues to shape the future of the concrete pump industry. Here’s what we can expect:

Electric and Hybrid Models

More eco-friendly models are being developed to reduce emissions and noise, making them suitable for urban areas with strict environmental regulations.

AI and IoT Integration

Smart pumps with sensors can automatically adjust pressure, flow rate, and volume based on pour conditions. These machines also provide real-time diagnostics and predictive maintenance alerts.

3D Concrete Printing Compatibility

Some manufacturers are experimenting with pumps compatible with robotic arms and 3D printing systems, laying the foundation for autonomous building solutions.

Compact Urban Models

City-centric designs with smaller footprints and noise-reduction features will be essential as urban job sites become tighter and more regulated.

Conclusion: concrete pump as a pillar of global construction progress

From its invention nearly a century ago to its current role in global megaprojects, the concrete pump has proven to be one of the most important innovations in modern construction. Its ability to deliver concrete faster, farther, and with more precision has not only improved building quality but also reshaped industry standards for safety, speed, and sustainability.

As the world moves toward smarter, greener, and more efficient construction practices, the concrete pump will continue to play a central role. Whether it’s enabling the skyline of New York, the tunnels of Singapore, or the new highways of Nigeria, this powerful machine is helping lay the foundations—literally and figuratively—of tomorrow’s world.