Exploring Pig Types in Pipeline Operations: Functions, Forms, and Future Innovations

Pipeline systems, whether used in oil, gas, chemicals, or even food production, rely heavily on maintenance tools to ensure optimal performance. One of the most essential and versatile tools in the pipeline maintenance toolbox is the pig. While the term might sound peculiar to those unfamiliar with pipeline terminology, pigs are sophisticated devices that travel through pipelines to perform critical tasks such as cleaning, inspecting, separating batches, and enhancing flow efficiency.

With varying needs across industries and pipeline configurations, different pig types pipeline operators choose from are specially designed for specific roles. From foam pigs to intelligent smart pigs, the selection depends on multiple factors including pipe diameter, type of fluid, pressure, length of run, and cleanliness requirements.

This article dives deep into the various pig types pipeline engineers and maintenance crews employ, discussing their design, application, and benefits in modern pipeline systems.

What Is a Pipeline Pig?

A pipeline pig is a device inserted into a pipeline that moves through the pipe’s interior, typically propelled by the product flow or a secondary medium such as compressed air or gas. As it travels, the pig performs one or more specific tasks without interrupting the pipeline’s operation.

Pigs are crucial in ensuring the pipeline remains free of blockages, contaminants, and corrosion, ultimately extending the pipe’s service life and maintaining product integrity.

2. Cup Pigs

Cleaning Category

Cup pigs feature flexible urethane cups attached to a central body. These cups create a tight seal, allowing the pig to push out product or debris effectively.

Key Features:

- Multiple cups increase sealing capability

- Available in single or multi-cup designs

- Can carry brushes or scraper attachments

Applications:

- Liquid displacement

- Wax, scale, or sediment removal

- Separating different batches of product

Cup pigs are commonly used in pipelines transporting crude oil or refined products.

See also: Technology in Commercial Cleaning: Innovations Shaping the Industry

3. Disc Pigs

Cleaning Category

Disc pigs use flat, circular discs made of polyurethane or rubber that scrape the interior of the pipeline as they move through it.

Key Features:

- Tighter seal than cup pigs in certain conditions

- Disc arrangement can be customized for different pipe sizes

- Less flexible than foam pigs but more robust

Applications:

- Heavy-duty cleaning

- Pigging in multi-diameter pipelines

- Preparing pipelines for inspection

Disc pigs are excellent for rigorous cleaning where reliability and durability are a must.

4. Brush Pigs

Cleaning Category

Brush pigs, often a subtype of mandrel pigs, include wire or nylon brushes that physically scrub the pipeline interior.

Key Features:

- Highly effective for removing hard deposits

- Often used with chemical agents

- May be equipped with forward and backward brushes

Applications:

- Rust or scale removal

- Debris cleanup after mechanical work

- Pre-inspection pipeline preparation

Brush pigs are an essential part of maintenance routines in pipelines prone to corrosion or buildup.

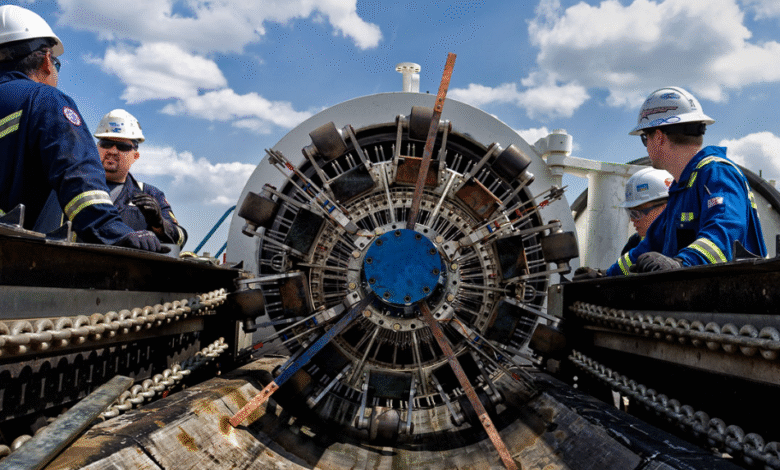

5. Mandrel Pigs

Utility and Cleaning Categories

Mandrel pigs feature a steel or aluminum body onto which different cleaning or sealing components can be attached, such as cups, discs, or brushes.

Key Features:

- Highly customizable and durable

- Suitable for high-pressure pipelines

- Components are replaceable

Applications:

- Versatile use including cleaning, separation, and gauging

- Long-distance pigging

- Pigging under extreme temperatures or pressures

Mandrel pigs are the go-to for pipelines requiring repeatable and reliable pigging operations.

6. Spherical Pigs

Utility Category

These pigs are inflatable or solid spheres that are inserted into pipelines to perform tasks such as liquid removal or flow regulation.

Key Features:

- Self-centering due to their shape

- Can pass through valves and short-radius bends

- Typically made from polyurethane

Applications:

- Dewatering gas pipelines

- Flow monitoring and batching

- Removing condensate from natural gas lines

Spherical pigs are a preferred option when low-resistance flow and mobility are key priorities.

7. Smart Pigs (Intelligent Pigs)

Inspection Category

Smart pigs are highly advanced pigs equipped with sensors, data storage, and communication systems. These pigs don’t just clean—they inspect.

Key Features:

- Equipped with technologies like magnetic flux leakage (MFL), ultrasonic testing (UT), or electromagnetic acoustic transducer (EMAT)

- Capture real-time data on wall thickness, corrosion, dents, and cracks

- High-resolution mapping and defect analysis

Applications:

- Integrity assessment of aging pipelines

- Regulatory compliance and risk management

- Asset life extension and predictive maintenance

Though more expensive, smart pigs provide invaluable insights and help pipeline operators take preemptive action to avoid failures.

Selecting the Right Pig Types for Your Pipeline

Choosing the right pig types pipeline engineers depend on involves considering several factors:

- Pipeline Diameter and Length: Larger or longer pipelines may require more robust or specially designed pigs.

- Product Type: Crude oil, gas, food, or chemicals may influence the material and design of the pig.

- Pipeline Age and Condition: Older pipelines might need inspection pigs or aggressive cleaning tools.

- Frequency of Pigging: Regular pigging operations benefit from reusable types like mandrel pigs; occasional use may call for foam pigs.

- Bends and Restrictions: Complex geometries favor flexible pigs.

Consulting with pigging system suppliers and engineers helps determine the best configuration for safety, efficiency, and budget.

The Future of Pigging Technology

As pipelines grow more complex and digital technologies continue to evolve, pigging systems are advancing in exciting ways:

- Smart Pigging Integration with IoT: Real-time data monitoring and remote diagnostics

- Autonomous Pigging: Self-charging or battery-less pigs that operate autonomously

- Biodegradable Pigs: For one-time use in environmentally sensitive areas

- 3D-Printed Pigs: Customized pigs made on-demand to fit unique pipeline configurations

The future of pigging is not just about maintenance—it’s about data, automation, and sustainability.

Conclusion

Understanding the different pig types pipeline professionals use is crucial to optimizing the efficiency, safety, and reliability of pipeline operations. Whether you’re cleaning heavy deposits, inspecting for corrosion, or simply separating batches in a food processing plant, there is a pig tailored to that specific task.

By selecting the right pig type and implementing a robust pigging strategy, industries can significantly cut costs, reduce environmental impact, and extend the life of their infrastructure. In a world increasingly focused on efficiency and sustainability, the humble pipeline pig continues to play a surprisingly powerful role.