How Do Plywood Sheet Thicknesses Influence Construction Outcomes?

Have you ever really wondered why plywood comes in all manner of thicknesses when you are planning and preparing for a new build or renovation? Some builders like to ignore this detail, but it can really influence the strength, safety, and practicality of any construction work. Intercepting the nature of plywood before selecting the plywood sheets will generate a lot of questions regarding thickness and its effectiveness on the expected result.

It offers a smoother and stronger working condition, regardless of whether one is installing flooring, building furniture or any structural components. And if you’ve had the experience of warping, twisting, or premature wear, then maybe the plywood size was a more significant influence than you realised.

So let’s take a look at how failure to choose the proper thickness could change the meaning of construction in Australia.

Why Thickness Matters in Construction

Different construction jobs set different layering strengths. Thicker plywood sheets tend to be better in terms of load-bearing capacity as opposed to thinner sheets, which are meant for lightweight applications. Wrong thickness selection will result in flooring sagging, poor joints, or surfaces chipping and distorting over time.

Australia’s wide-ranging climate, from humid coastal swathes to the dry heat of the interior, is also involved in the plywood performance. The thicker alternatives are resistant to moisture absorption, movement, and temperature adjustment. The thinner plywood could be easier to install, but might not resist very demanding environments without proper application.

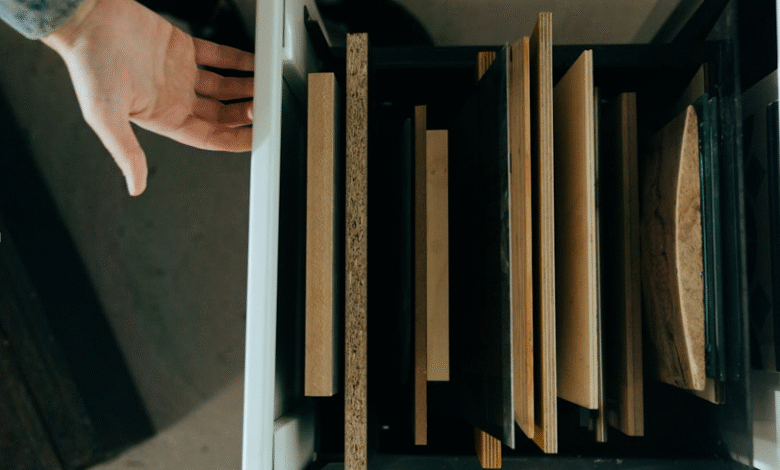

Common Thicknesses and Their Construction Uses

Plywood usually ranges from 3 mm to 25 mm, and each size serves a specific purpose:

- 3–6 mm sheets: Very good for curved surfaces, cabinetry backing, drawer bottoms, and decorative wall panels. Theseplywood sheets are thin, flexible and easy to mould.

- 9–12 mm sheets: These can also serve as general-purpose tables, internal wall cladding, and shelving. They maintain a balance between strength and workability.

- 15–18 mm sheets: They are mainly used for flooring, construction bracing, and heavy-duty furniture. Because of their strength, they can bear more weight and will keep from bending.

- 21–25 mm sheets: Most suitable for structural flooring systems, roof substrates, and other industrial application product lines, well-built to accommodate heavy weights and use across time.

When you match the thickness to your project needs, you boost the longevity and safety of your build.

See also: Introduction To Business And Management

Impact on Aesthetics and Stability

The said thickness affects strength, but it also determines how visually and tactually final products turn out. For example:

- Plywood-thickened flooring will decrease vibration and noise in the room.

- Thin sheets help to create smooth, easily modern finishes in furniture.

- Thickness chosen rightly keeps surfaces even, stable, and pleasing to the eye.

Too thin a sheet may allow bowing or movement over time, while excess may introduce unwanted weight or cost.

Conclusion

Each millimetre makes a difference in choosing the right thickness of plywood sheets, which means the success of any construction project. Matching the sheet thickness to your project requirements ensures a stronger build, less hassle, and better overall performance across Australia in the long run.